Just Hired!

RCO Engineering

Aerospace Material Analyst

Joshua RoyMaterial Analyst

MSU SCM graduate with a passion for process optimization and innovative technology solutions. Discover my experience and journey below.

About Me

Hello, I am Joshua Roy

Graduate of Michigan State University with a degree in Supply Chain Management and an Information Technology minor. Known for my strengths in plastics manufacturing processes, inventory/warehouse management, material handling, training documentation, lean, and graphic design.

Feel free to explore my work and get in touch if you'd like to connect!

Career pivot: hat model

My greatest supporters

Resume

Key Highlights

- Developing proficiency in: SAP, Epicor, R, SQL, Python, Excel, Tableau, and Smartsheet.

- Experienced in operating and creating supply chain solutions.

- Background in materials and plastics manufacturing.

- Proven track record of managing high quality deliverables.

- Excellent communication and training abilities.

Reference Letters

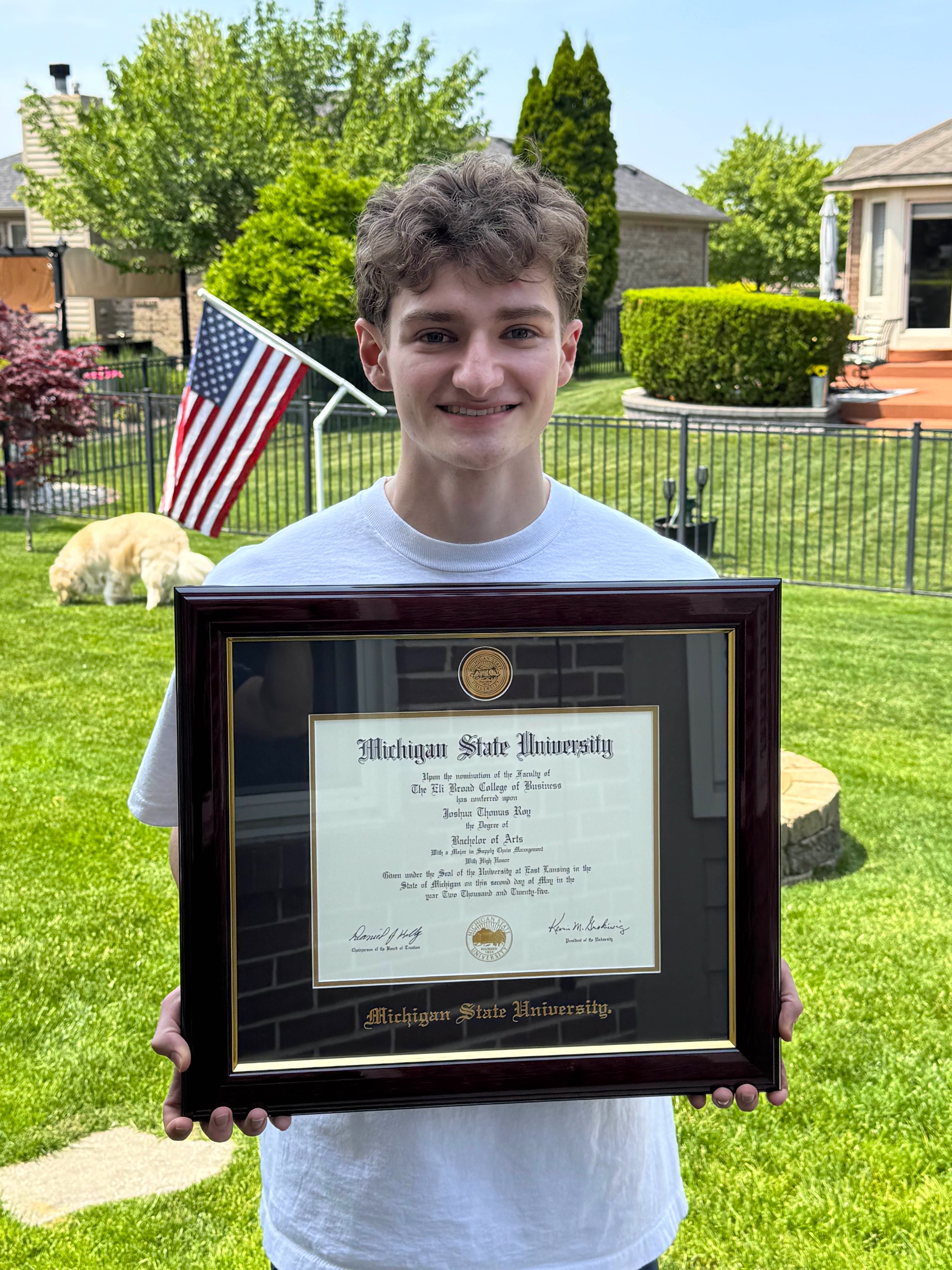

Education

GPA: 3.98/4.00

- Relevant Coursework: Data Analytics, Database Management, Logistics, Procurement, Operations Management

- Graduated with High Honor; Dean's List: All eligible semesters (4)

GPA: 4.00/4.00

- Focused on foundational business principles and general education requirements

- Decided to pursue Supply Chain Management

GPA: Valedictorian (4.04/4.00 weighted)

- Active in FIRST Robotics Competition Team 453 - Rock'Em Sock'Em

- National Honor Society member

Experience

- Developed system to scrape online car marketplace sites, store key information, and relay it to 500+ Michigan dealerships

- Built project management tools including Gantt charts, timesheets, and training guides to coordinate team efforts and maintain transparency with client and project director

Key Skills & Technologies:

- Created Smartsheet forecasting tools for top 5 customers, enabling proactive identification of capacity risks across machines, materials, manpower, and methods

- Gained experience with core materials management concepts including cycle counting, bin audits, reconciliation, lean principles, and materials risk escalation to formulate Standard Operating Procedures and training videos

Key Skills & Technologies:

- Reviewed production schedules to anticipate job changeovers and prepare materials and equipment for press transitions

- Maintained proper environments for 25+ materials daily, supporting process quality and production efficiency

Key Skills & Technologies:

- Inspected plastic parts by referencing quality work instructions to discard scrap and forward acceptable pieces to secondary assembly or packaging

- Operated Epicor to input part counts, supporting inventory accuracy and ensuring reliable data for production decisions

Key Skills & Technologies:

My Story

Loading timeline...

Future Aspirations

My ambitions drive me to optimize systems, embrace innovation, and contribute to the ever-evolving world of supply chain and technology.

To design and implement intelligent, tech-driven supply chain solutions that increase efficiency, resilience, and sustainability

To grow into leadership roles where I can drive transformation, mentor emerging professionals, and align supply chain operations to the goal

To see where my journey of lifelong learning and curiosity directs me to help make the world a better place

My Library

Welcome to my library! Here are some of the books I've recently dived into. It's a glimpse into the stories and ideas that inspire and entertain me.

Connect With Me

Connect with me on these platforms. I look forward to hearing from you!